VIP member

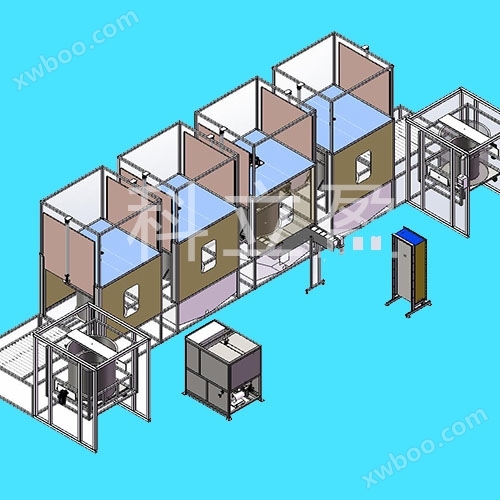

Stainless steel cylinder cleaning line CXCS series

Stainless steel cylinder cleaning line CXCS series

Product details

Stainless steel industrial cylinder cleaning line, also known as cylinder cleaning production line, thisThe system is used to clean the three-dimensional mixing tank, mobile pulling cylinder, transfer cylinder, and turnover cylinder. It controls the opening of the water pump, the control of various valves, and the action control of various hydraulic mechanisms through an electronic control system to perform three-dimensional blind spot coverage for cyclic cleaning of the pulling cylinder. The cleaning line operates in a fully automatic mode, requiring operators to monitor and control the entire cleaning process and provide assistance.

Industrial cylinder cleaning lineCleaning station

Top bucket flipping, internal scraping, spray DMF station, high-pressure internal and external cleaning, water removal, blowing, flipping, bottom bucket

Industrial cylinder cleaning line workflow

1. Manually push the cylinder into the upper bucket position with the opening facing upwards, and the sensor detects the bucket.

2. The flipping mechanism flips the cylinder 180 ° and turns it onto the transition conveyor line.

3. The conveyor line starts working, driving the cylinder to reach the DMF washing station. The lifting mechanism controls the door of the cleaning room to close. DMF is pressurized by a pump station to form high pressure, transported through pipelines, and reaches the rotary cleaner. The lifting mechanism rises, driving the rotary cleaner into the cylinder, and then spraying high-pressure water for cleaning, cleaning the inside of the bucket, and then flowing back to the solvent tank (note: the water used for internal cleaning is DMF, collected by the waste liquid collection system).

4. Immediately, the conveyor line sends the bucket to the clean water washing station, and the lifting mechanism lifts the cleaning head into the inside of the cylinder, then sprays high-pressure clean water to clean the inside of the bucket. The external cleaning rotating component nozzle cleans the outside of the cylinder 360 ° without dead corners.

5. Immediately, the conveyor line transports the cylinder to the dehydration and drying position. First, excess moisture inside and outside the cylinder is blown off, and then hot air is sent into the drying room using a steam heat exchange device to dry the remaining water, with an effective drying rate of 95%.

6. Then transport the cylinder to the transition position.

7. Immediately, the cylinder reaches the flipping station, and the clamping mechanism positions and clamps the barrel. The flipping mechanism flips the barrel 180 °, and the clamping mechanism is released.

8. Manually gather the buckets in the designated area to complete a cleaning cycle for the cylinder.

Ordering Example: CXCS (Model) - P (Pressure) - Configuration

Ordering Example: CXCS (Model) - P (Pressure) - Configuration

Cylinder cleaning equipment - animation

Online inquiry